eddows, https://stock.adobe.com/uk/images/166760531, stock.adobe.com

Background

Heart valve related diseases remain a significant public health issue affecting an estimated 2% of the population with 4% of those over 65 having aortic stenosis (AS), a narrowing of the valve opening which can lead to heart failure. The traditional treatment for AS, surgical aortic valve replacement, is a highly invasive open-heart surgical procedure that is not suitable for all patients. Transcatheter aortic valve replacement (TAVR) has emerged as a less invasive alternative, rapidly becoming the dominant treatment for AS. However, certain clinical complications persist, including thromboembolic risk and long-term durability issues associated with the use of tissue valves. As the utilization of TAVR continues to increase in younger and lower-risk patient populations, identifying a solution that mitigates these complications is of growing clinical significance. Polymeric valve solutions aim to address the shortcomings of tissue valves by providing improved resistance to damage during crimping and deployment, and through the use of hemocompatible materials with antithrombotic properties.

Technology

Researchers at Stony Brook University, in collaboration with researchers at the University of Arizona, have developed a group of novel polymeric heart valve replacement devices to address heart valve stenosis. These valves combine sutureless casting technology and unique design optimizations to overcome the intrinsic limitations of current tissue-based TAVR products. The polymer, xSIBS, is ideal for TAVR because of its excellent biocompatibility, fatigue resistance, calcification resistance, and ease of manufacturing. The researchers have valve solutions specifically designed for TAVR, as well as devices for transcatheter tricuspid and venous applications. They have also developed valves with asymmetrical leaflets that are specifically optimized for bicuspid aortic valve anatomy, providing a targeted solution for a congenital heart defect which is currently not addressed by any commercially available valve.

Advantages

Sutureless design - Increased durability - Decreased inflammatory response - Ease of manufacturing - Varied leaflet designs optimized for specific applications

Application

Transcatheter aortic valve replacement - Bicuspid aortic valve stenosis - Tricuspid valve replacement - Venous valve systems

Inventors

Brandon Kovarovic, Research Assistant, PhD, Biomedical Engineering

Danny Bluestein, Professor, Biomedical Engineering

Ryan Helbock, , Biomedical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Applications Published: WO2023/168270, WO2023/168278, WO2025/054300

auremar, https://stock.adobe.com/uk/images/181192937, stock.adobe.com

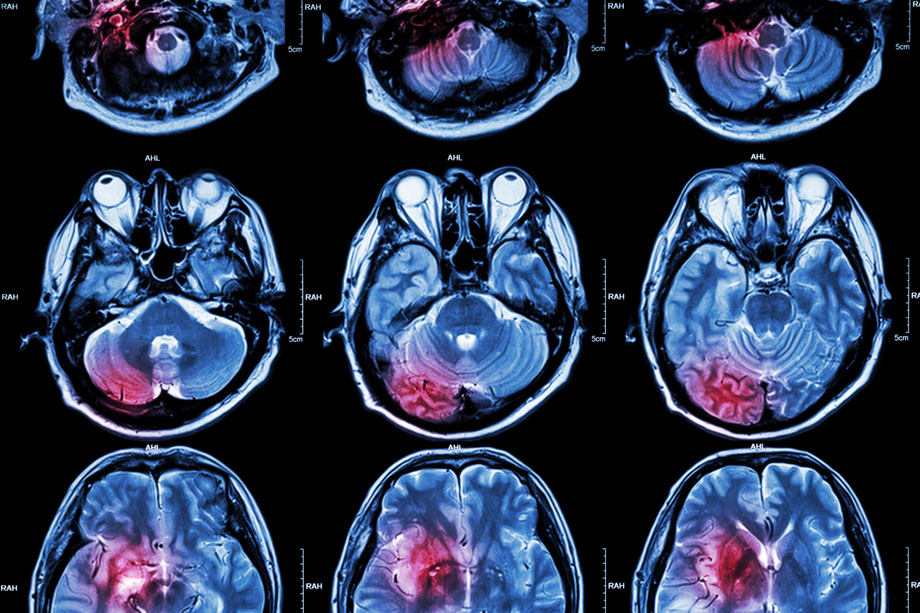

Background

Assessing the functional state of the brain and predicting recovery of consciousness following acute brain injury (ABI) remains a major unsolved clinical problem. Currently, behavioral measures of recovery with scoring systems such as the Glasgow Coma Scale (GCS) and the Coma Recovery Scale-Revised (CRS-R) are used. However, these methods are low resolution and depend on subjective impressions by bedside clinicians. Low-amplitude responses may not be observed, and patients may be mischaracterized as unconscious when awake. Previous attempts using techniques like electromyography (EMG) rely on sampling of potentially functional muscles, but brain injury patients often have injuries which interfere with analysis of motor behavior. There remains a need for objective techniques to measure the functional state of the brain and predict recovery after ABI.

Technology

SeeMe is a novel facial analysis tool to monitor behavior recovery in comatose patients following acute brain injuries. SeeMe provides a real-time brain-computer interface for measuring low-amplitude voluntary movements that are difficult to detect with the naked eye. By analyzing low-amplitude facial movements occurring in response to specific auditory commands, SeeMe provides the first automated technique to detect early signs of neurological recovery in ABI patients. SeeMe is simple to use and can inform clinical decision-making.

Advantages

Objective measurement of consciousness - Reduce the number of mischaracterizations - Simple to use - Automated

Application

Detecting consciousness following acute brain injury - Behavior quantification and assessment

Inventors

Sima Mofakham, Research Scientist/Research Assistant Professor, Neurosurgery

Charles Mikell, Assistant Professor, Neurosurgery

Xi Cheng, ,

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Pending

homonstock, https://stock.adobe.com/uk/images/94839391, stock.adobe.com

Background

Given recent advances in size, durability, and cost, the use of portable ultrasound systems has expanded within the prehospital environment. Point-of-care ultrasonography (POCUS) describes focused diagnostic ultrasound exams performed at the patient’s bedside, providing real-time information to guide proceeding clinical management. POCUS is an invaluable tool for patient evaluation, but presents with unique operational challenges when used in prehospital environments such as ambulances and medical helicopters. POCUS is operator dependent, so the process of obtaining and interpreting images can be affected by the vehicle movement encountered in these prehospital environments. As such, it is crucial for prehospital clinicians to be able to learn and maintain POCUS skills within their own unique work environment. However, existing ultrasound training systems do not properly account for the dynamic environments faced by prehospital clinicians, limiting their use by prehospital clinicians.

Technology

Stony Brook University researchers have developed a POCUS simulation system tailored for educational use in dynamic prehospital settings such as ambulances and medical helicopters. The system is configured to compensate for movement, allowing the probe to report its true orientation in relation to the target and enabling the display of an appropriate image in mobile environments. The technology permits the simulation of diverse scenarios, providing learners the ability to practice obtaining and interpreting point of care ultrasonography exams while in their own unique work environment.

Advantages

Provides real-time, situational training - Simulates unique work environments to enhance learning - Usable in mobile environments

Application

Medical training programs/institutes - Field medic training - Skill maintenance

Inventors

Lauren Maloney, Emergency Physician, Department of Emergency Medicine

Griffin Walker, Undergraduate Student, Department of Technology and Society

Thea Vijaya Kumar, Undergraduate Student, Mechanical Engineering

Alexander Mertz, Undergraduate Student, School of Health Technology and Management

Daniella Hébert, Undergraduate Student, Mechanical Engineering

Taelyn Kupec, Undergraduate Student, Emergency Medicine

Sean Reagan, , College of Engineering and Applied Sciences

Alexander Eichert, Undergraduate Student, Biomedical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Application Published: WO2025/054466

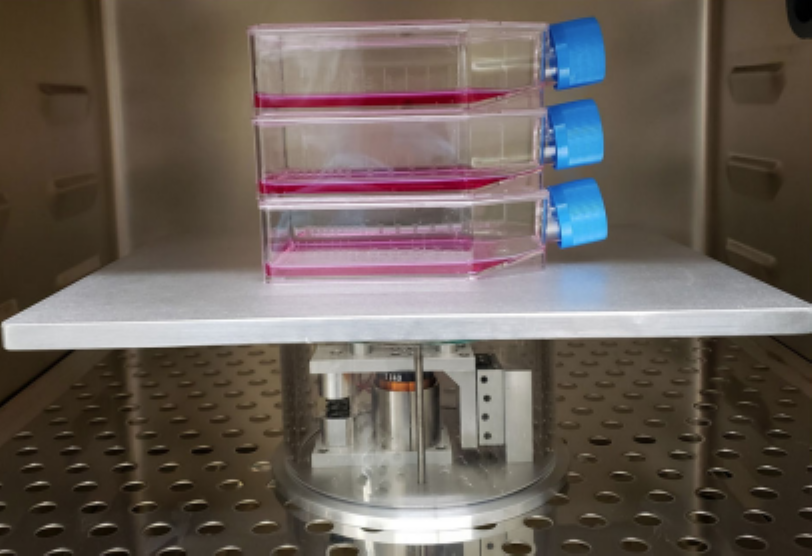

Background

The CAR T cell therapy process, from patient apheresis to manufacturing facility and back to the treatment center, currently takes anywhere between 2-4 weeks and necessitates a complex network of transportation, scheduling and skilled labor to be successfully executed. This cascade of events is highly subject to delays which can negatively impact patient outcomes. A substantial fraction is spent on the ex vivo cell expansion phase alone, using IL-2, a T cell growth factor and antigen cell present mimicking agents. To meet the time-sensitive demands of cancer treatment with a non-chemical approach, Dr. Rubin and Dr. Chan’s team propose to expedite the expansion phase for high-throughput CAR T cell manufacturing using mechanical stimulations.

Technology

Dr. Rubin and Dr. Chan’s team have demonstrated that mechanical signals delivered via low intensity vibration (LIV) have a proliferative effect on human Pan T cell cells. LIV can be delivered in sterile cell culture conditions through vertical oscillation of a custom feedback-controlled device. Optimization parameters include the amplitude, frequency, duration and refractory period of the sinusoidal LIV signals. Promoting proliferation of the T cells shortens the cell expansion phase of the biomanufacturing process and will shorten waiting (vein-to-vein) time in CAR T cell therapy.

Advantages

Novel system with optimized parameters - Promotes proliferation of T cells - Shortens cell expansion phase - Patient-Centered - Widely applicable

Application

Autologous cell therapy - Hematology products - CAR-T Cell Therapy

Inventors

Mei Lin (Ete) Chan, Research Assistant Professor, Biomedical Engineering

Clinton Rubin, Distinguished Professor, Biomedical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Application Published: PCT/US2021/034742

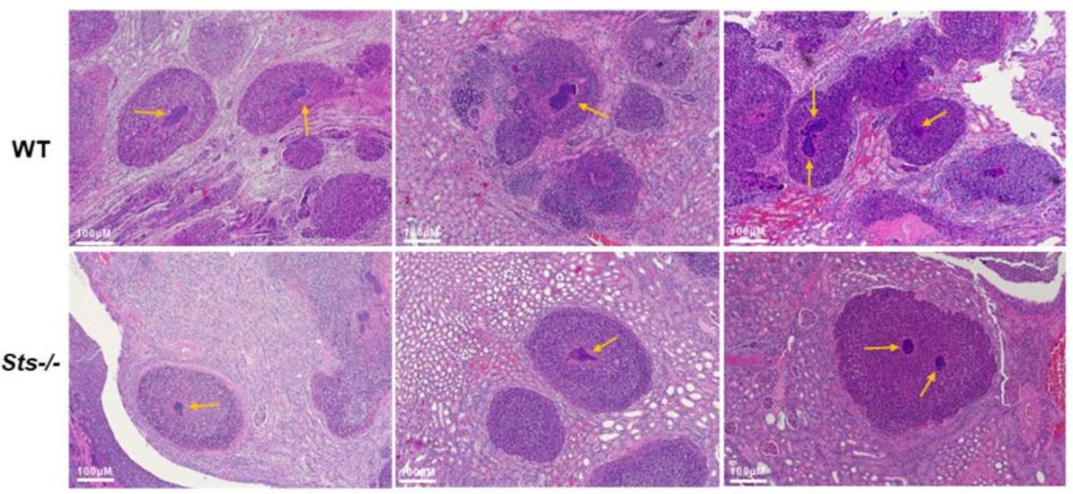

Reduced size of Staphylococcus abscess communities within Sts-/- mouse kidney abscesses

Background

Phosphatases Sts-1 and Sts-2 are two homologous proteins in humans which act as negative regulators of T cell receptor (TCR) signaling. These proteins regulate immune signaling through activity catalyzed by their shared C-terminal histidine phosphatase (HP) domain. The HP domain is a tyrosine phosphatase which dephosphorylates the kinases Syk and ZAP-70.

Technology

Dr. Nicholas Carpino developed a novel mouse model that has demonstrated resistance to systemic infection by human fungal pathogen Candida albicans, Gram-negative bacterial pathogen Francisella tularensis, and Gram-positive pathogen Staphylococcus aureus. The mouse model presents the double knockout of Sts-1 and Sts-2. This modification increases ZAP-70 phosphorylation and activation, which leads to enhanced downstream TCR signaling and elevated cytokine production. The absence of these proteins results in a marked increase in T cell proliferation and altered immune signaling pathways. These mutations enable the mice to withstand lethal inoculums of dangerous pathogens.

Advantages

Useful for testing novel compounds and treatment strategies - Provides a better suited animal model for studying antimicrobial immunity

Application

Mouse Model - Research Tool - Therapeutic Screening - Drug Delivery

Inventors

Nick Carpino, Associate Professor, Microbiology and Immunology

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Free Photos, Pixabay, CC0

Background

Current day algorithms governing how medical devices deliver stimulation to patients have not changed in well over 50 years and cannot account for neurological variabilities across individuals that come about from differences in genetics, lifestyle factors, and sustained injuries. As a result, clinicians are experiencing highly inconsistent patient outcomes, with 30%-90% of individuals not responding to treatment at all, depending on the disease. A large quantity of research in the fields of computational and systems neuroscience has demonstrated that the clinical state-of-the-art is insufficient to remedy many pathologies and must be re-invented for better results.

Technology

Escape-the-Maze (EtM), is a brand-new type of reinforcement learning algorithm. EtM is the first of its kind and is installed on existing medical devices in a closed-loop recording-stimulating setup with the brain circuit of interest, where it leverages the patient’s unique neural activity to guide the electrical activity out of the unwanted state e.g coma. Due to EtM’s versatility, there are a wide array of applicable markets associated with neuropsychiatric and movement disorders such as obsessive compulsive disorder (OCD), as well as disorders of consciousness.

Advantages

Personalized algorithms to treat various disorders - Automatically modulates stimulus applied by medical devices - Hardware agnostic (both invasive and non-invasive treatments)

Application

Treatment of neuropsychiatric, movement, and consciousness disorders.

Inventors

Ian Jordan, , Department of Applied Mathematics and Statistics

Il Park, Assistant Professor, Neurobiology and Behavior

Josue Nassar, , Electrical and Computer Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Application Published: WO2023/196280

In-silico data

Source: SciePro, https://stock.adobe.com/uk/87073740, stock.adobe.com

Background

Infection by Gram‑negative bacteria such as Pseudomonas aeruginosa, β‑lactamase producing (ESBL) Enterobacteriaceae, and Acinetobacter baumannii is a major health problem, especially in the case of hospital‑acquired infections. Current estimates indicate that Pseudomonas aeruginosa is responsible for about 10% of all hospital-acquired infections such as pneumonia, urinary tract infections, intra‑abdominal infections, and catheter‑associated bloodstream infections. In addition, there is an increasing level of resistance to current antibiotic therapies, which severely limits treatment options. An increasing rate of multidrug-resistant (MDR) Pseudomonas strains (from 4% in 1992 to 14% in 2002) has led to the use of drugs such as polymyxin that have serious side effects. Compared to infections caused by non‑resistant strains, resistant and MDR pathogens increase the average length of hospital stay by about 5 days and 17 days, respectively. Gram‑negative bacteria are unique in that their outer membrane contains lipopolysaccharide (LPS), which is essential for bacterial viability. Lipid A is the major lipid component of LPS, and inhibition of Lipid A biosynthesis is lethal to bacteria. LpxC is the enzyme that catalyzes the first committed step in the Lipid A biosynthetic pathway, and it is a suitable target for the development of antibiotics.

Technology

Researchers at Stony Brook University have developed inhibitors of the LpxC enzyme with improved safety profiles compared to existing compounds. This is achieved by synthesizing inhibitors that dissociate slowly from LpxC and have extended activity at low drug concentrations so that they can be administered at lower doses. The result is reduced exposure to antibiotics, decreased side effects, increased compliance, and reduced drug resistance. Thus, long residence time inhibitors of LpxC are realized to treat serious infections caused by MDR‑pathogens with minimized impact on the microbiome.

Advantages

Long residence time - Reduced exposure to antibiotics - Improved safety profiles

Application

Treatment of drug-resistant bacterial infections. Treatment of Gram‑negative bacteria. Treatment of Pseudomonas aeruginosa.

Inventors

Peter Tonge, Professor, Chemistry

Fereidoon Daryaee, Senior Scientist, Chemistry

Sneha Basak, , Chemistry

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Application Published: PCT/US2022/074510

Source: BillionPhotos.com, https://stock.adobe.com/uk/334981063, stock.adobe.com

Background

Resistance to chemotherapy can be a highly complex issue, with epigenetic alterations playing a key role in tumorigenesis and chemotherapy resistance. The failure to treat several advanced solid tumors can be often attributed to resistance to fluoropyrimidine-based and gemcitabine chemotherapy. One form of epigenetic alteration includes changes in expression of non-coding RNAs. Non-coding RNAs, such as microRNAs (miRNAs), have been found to regulate several key targets that are responsible for cancer stemness, and function as oncogenic miRNAs or tumor suppressor miRNAs. In particular, miR-15a is one of the major tumor suppressor miRNAs that is either lost or has reduced expression in many cancer types. Thus, restoration or miR-15a poses a potential strategy for suppressing multiple oncogenic targets.

Technology

Dr. Jingfang Ju and his team have developed a platform for modifying miRNAs and using the modified miRNAs as novel cancer therapeutics. The unique design of the miRNAs enhances the stability, therapeutic efficacy, and ease of delivery. The miRNA modification platform replaces the uracil and cytidine bases with anticancer nucleoside analogs, such as the chemotherapeutic drugs 5-Fluorouracil (5-FU) and gemcitabine (Gem). The miRNAs are further modified by also integrating methotrexate (MTX). As an example, Dr. Ju designed and synthesized MTX-5-FU-Gem-miR-15a. The rationale behind this design is that folate receptor/reduce folate carrier, which is elevated in cancer cells, will be used to improve tumor specificity. MTX, once broken down from the miRNA memetic, will add to the tumor killing effect of the modified miRNA tumor suppressor.

Advantages

Delivered to cancer cells with no transfection reagent – More potent inhibitors of cell proliferation – Enhanced stability

Inventors

Jingfang Ju, Professor, Pathology

Iwao Ojima, Distinguished Professor, Chemistry

John Yuen, Graduate Student, Pathology

Lei Chen, Post-doc fellow, Chemistry

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Application Submitted

Header image is purely illustrative. Source: Rawpixel.com, stock.adobe.com/uk/244424672, stock.adobe.com

Background

Terahertz time-domain spectroscopy is a technique that has shown promise in biomedical imaging for the diagnosis of burn wounds. However, current portable terahertz imagers are either limited by size, requiring motion stages to move a scanning head over a sample, or by alignment issues associated with their image acquisition techniques. The current state of the art technique for burn examination remains subjective clinical examination, where clinical diagnosis is often delayed for days to assess if the burn has reached its maximum depth. There remains a need for high-speed, objective diagnostic tools to improve accuracy while assessing burn depth and affected surface area, which are pivotal factors that guide therapeutic decision making.

Technology

The inventors have developed a portable handheld spectral reflection (PHASR) scanner which is alignment-free, and can acquire three-dimensional spectroscopic images in the terahertz range between 0.1 and 3 THz. The PHASR scanning device uses an asynchronous optical sampling system to achieve quick scan times, and is only attached by an umbilical. The device’s portability and quick scan times allow it to be used in clinical settings where previous devices could not be used. The device has been used to characterize burn injuries in animal studies, and a human clinical trial is being planned to further test the use of the device for diagnosing burn wounds and predicting wound healing outcomes.

Advantages

Provides an objective assessment of burn wounds - Fast image acquisition - Portable

Inventors

Mohammad Arbab, Associate Professor, Biomedical Engineering

Zachery Harris, , Biomedical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

US Patent Issued: US12146790, Patent Application Published: WO2020185886

Human Data

Please note, header image is purely illustrative. Source: Stockdevil, Adobe Stock.

Background

Radiopharmaceuticals are agents which enable non-invasive patient diagnosis and personalized therapeutic intervention strategies. Radionuclides used in nuclear medicine applications must be purified after nuclear synthesis to separate them from the target material. Radioisotopes used in radiopharmaceutical production often have short half-lives, and require fast, simple and modular synthesis methods to produce the target with high yield, purity, and molar activity. However, current radiosynthesis strategies are time-consuming, multi-step processes which often leads to the decay of a significant amount of the radionuclide before it can be used. There remains a need for improved radiosynthesis strategies which can condense the steps required to prepare radiopharmaceuticals in a more rapid, clean fashion than existing methods.

Technology

The Boros Lab has developed a solid-phase, concerted separation and radiosynthesis strategy with photochemical release of radiotracers in biocompatible solvents to prepare injectable radiopharmaceuticals. This Solid Phase Radiometallation Photorelease (SPRP) method involves the selective capture of the radionuclide by a solid-phase appended peptide chelator conjugate, allowing for simultaneous radiochemical labeling and selective removal of excess trace metal impurities from large stock volumes. Photochemical release provided radiopharmaceuticals with >95% radiochemical purity and excellent in vivo performance in a preclinical mouse model. SPRP has the potential to accelerate and simplify selective metallation beyond the radiochemical synthesis of radiopharmaceuticals, and provide a versatile platform technology for the development of a large class of metal-based pharmaceuticals

Advantages

Production of larger dose quantities - Faster production - Simultaneous radiochemical labeling and purification.

Application

Production of ready-to-inject target radiopharmaceuticals. Cancer diagnosis and treatment.

Inventors

Eszter Boros, Assistant Professor, Chemistry

Dariusz Śmiłowicz, Postdoctoral fellow, Chemistry

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

Patent Application Published: PCT/US2023/064637

peopleimages.com, https://stock.adobe.com/uk/images/1120911108, stock.adobe.com

Background

Therapeutic monoclonal antibodies (mAbs) have emerged as a dominant therapeutic modality to treat cancer, immune disorders, and infectious diseases such as high-mortality Carbapenem-resistant Klebsiella pneumoniae (CR-Kp). Although mAbs may combat the rising antibiotic resistance cases, antigenic diversity limits mAbs as a broader therapy- different strains often require different antibodies. There is an urgency to develop novel treatments to combat multidrug resistant pathogens; one of them being CR-Kp strain sequence type ST258, which is the most prevalent CR-Kp strain in the United States (60%). ST258 CR-Kp strains express different wzi types (wzi 50, 29, 154), however, so far only wzi154 strains have been successfully targeted by mAbs. Therefore, there is a specific need for a broader treatment method for CR-Kp strains that encompasses more of the wzi types.

Technology

The inventors have developed a murine mAb 24D11 (IgG2b isotype) by vaccinating mice with purified wzi50 type capsular polysaccharide (CPS). Cross-reactivity and protective efficacy of mAb 24D11 were confirmed against CR-Kp of 3 prevalent CPS types (wzi29, wzi154, and wzi50) using both in vitro and in vivo infection models. Using a murine intratracheal infection model, it has also been determined that mAb 24D11 reduced lung burden and dissemination of CR-Kp expressing different wzi-types, not only pre, but also if given 4 hours post infection. This is the first monoclonal antibody that exhibits cross-protective efficacy against multiple ST258 CR-Kp strains; it overcomes a major barrier to successfully target wzi29, a major CPS expressed by ST258 CR-Kp including that which caused the CR-Kp outbreak at the NIH in 2009.

Advantages

Cross-reactivity and protective efficacy against multiple wzi CR-Kp - Antibody is effective pre and 4 hours post infection - Antibody reduced lung burden and dissemination of CR-Kp.

Application

Klebsiella infections

Inventors

Kasturi Banerjee, , Medicine

Bettina Fries, Professor, Medicine

Michael Motley, , Medicine

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

WO2023205731

Animal data

Source: Kateryna_Kon, https://stock.adobe.com/uk/188725387, stock.adobe.com

Background

One third of the world’s population is infected with tuberculosis (TB). In 2014, there were 1.5 million TB related deaths. There are drugs to combat the bacteria by attacking the bacteria directly. The current recommended treatment regimen for TB begins with a two-month intensive therapy using isoniazid, rifampicin, pyrazinamide, and ethambutol followed by four months of treatment with isoniazid and rifampicin. The issue is that drugs like isoniazid lose their efficacy over time. As an alternative, bedaquiline has stepped in with a new approach to handle TB. Bedaquiline is designed specifically to target mycobacterial adenosine triphosphate synthase. This enzyme is produced by the mycobacteria and is essential for the supply of energy to the mycobacterium tuberculosis and other bacteria in the same family. The issue is that the drug is expensive for a full 6 month treatment process and depending on the person undergoing treatment, may not be enough on its own.

Technology

New variations of 6-azasteroids have improved the ability to aid bedaquiline and lessen the amount necessary for tuberculosis treatment. Tuberculosis uses the host body’s sterols, such as cholesterol, to reproduce. Normally the body would regulate cholesterol levels with testosterone, but testosterone is often transformed into dihydrotestosterone by 5a-reductase. 6-azasteroids can inhibit 5a-reductase, which leaves testosterone to lower the amount of cholesterol in the body. This starves the tuberculosis, relieving much of the strain on bedaquiline. The drug can now target the bacteria located at other sterols, such as the glycerols which are vital for other bodily functions. 6-azasteroids have been cited for their low toxicity and ability to be spread throughout the body with little to no issues from side effects when tested in rats and dogs. The 6-azasteroids may be a promising supplemental treatment for those undergoing tuberculosis treatment, and can possibly lead to faster recovery with less use of current on the market drugs.

Advantages

Lowers required dosage of TB treatment of drugs - Improved recovery times - Decreased side‑effects

Application

To supplement bedaquiline in tuberculosis treatment. Can also target bacteria located at other sterols.

Inventors

Nicole Sampson, Professor and Interim Dean, Chemistry

Joshua Werman, Graduate Research Assistant, Chemistry

Tianao Yuan, Graduate Research Assistant, Chemistry

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

PCT Filed

Source: Kadmy, https://stock.adobe.com/uk/314277826, stock.adobe.com

Background

In nuclear reactor environments, particularly within fission and fusion reactor cores, effective radiation shielding is critical to ensure both the safety and longevity of the structural components. These reactor cores are constantly exposed to intense neutron and gamma/x-ray radiation, which can degrade materials and components over time and pose significant risks to both the reactor’s integrity and the surrounding environment. As reactor technologies advance and power outputs increase, the demand for more efficient and robust shielding materials that can simultaneously manage multiple types of radiation while maintaining structural strength becomes increasingly important. The ability to protect against diverse radiation forms without compromising the reactor’s mechanical stability is essential for the sustainable and safe operation of next-generation nuclear facilities. Current shielding solutions typically employ separate materials and layered approaches to address different types of radiation, which introduces several inefficiencies and limitations. For instance, high electron density materials like lead or tungsten are used for gamma/x-ray shielding, while neutron protection often requires a combination of moderating substances such as water or polyethylene and neutron-absorbing elements like boron or hafnium. This multi-layered strategy not only consumes valuable space within the reactor design but also fails to optimize the overall shielding effectiveness. These shortcomings highlight the need for efficient shielding solutions that can streamline reactor designs and enhance radiation protection.

Technology

The technology is a novel structural steel composite for mixed neutron and electromagnetic radiation shielding application. The composite has an iron-based steel alloy matrix and a metal-hydride (MH) secondary phase(s) with one or more high neutron-absorbing and moderating MHs. By utilizing an innovative fabrication process at lower temperature and pressure, the steel preserves the hydride phase, allowing for up to 55% metal hydride content without decomposition, enabling the production of thick plate geometries while maintaining the integrity of the metal hydrides. What sets this technology apart is its ability to combine neutron moderation, neutron absorption, and electromagnetic shielding into a single, cohesive and structural material. Traditional shielding solutions typically require separate layers or materials to address each type of radiation, leading to spatial inefficiencies and compromised performance. In contrast, this composite steel streamlines the design by integrating all necessary shielding functions, resulting in enhanced effectiveness in reducing fast neutron flux and superior structural integrity in high-radiation environments. This steel composite outperforms conventional materials like water, boronated steel, and boron carbide, offering a more efficient use of space, improved shielding performance, and a simplified design. This makes it a significant advancement for nuclear applications demanding comprehensive radiation protection without sacrificing structural functionality.

Advantages

Integrates neutron moderation, absorption, and electromagnetic shielding into a single material, simplifying reactor design. Superior shielding effectiveness against fast neutrons compared to traditional materials. Maintains structural integrity and mechanical strength in high-radiation environments. Allows up to 55% metal hydride content without decomposition. Efficient use of space by eliminating the need for separate shielding layers. Optional inclusion of borides for enhanced neutron absorption or electromagnetic protection.

Application

Nuclear reactor shielding Fusion reactor components Spacecraft radiation protection Medical radiation facilities Particle accelerator shielding

Inventors

Lance Snead, , Materials science and Chemical Engineering

David Sprouster, Assistant Professor, Materials science and Chemical Engineering

Licensing Potential

Commercial partner, Licensing

Licensing Status

Available

Licensing Contact

Jillian True, Licensing Specialist, Intellectual Property Partners, Jillian.True@stonybrook.edu,

Patent Status

Provisional Patent Application Filed

Prototype Demonstration

Background

Clinically viable prodrugs release activated drug molecules at the site of interest, requiring close spatiotemporal control. Bond cleavage strategies for the release of the activated drug often incorporate triggers such as pH, UV irradiation, or enzyme proteolysis. The reliance on such triggers to modulate drug selectivity, function, and pharmacokinetics can drastically limit drug efficacy and applicability. Stimulus-responsive prodrugs involving metal ions also depend on external stimuli or catalyst concentration, which can limit the threshold abundance of the biological target. Selective, metal ion-mediated amide bond cleavage is a well-characterized process in nature and has been used for prodrug activation. However, current strategies are limited in vivo by their reliance on labile metal ion binding and bimolecular reaction mechanisms.

Technology

The Boros lab has developed a new radiopharmaceutical agent as an imaging agent that will release a metallodrug containing Gallium-67/68, Scandium-3, or Copper-3 to the tumor sites. Unlike traditional imaging agents, the new compound will be able to release the metallodrug without the need to use other potentially harmful activation techniques such as changing the pH or UV light exposure, which are invasive procedures. Once the compound has been exposed for long enough to normal body heat, the metallodrug will be released by a N-O acyl shift, as to preemptively cleave the amide bonds holding the radiometals. Once the acyl shift has been performed, the local pH will lower to 5.5 with an immediate adjustment of the reaction temperature. This gives the biomarker guide enough time to deliver the radiometal to the desired tumor sites without having to use a large amount of imaging agents.

Advantages

Autolytic, independent release of metallodrug - Not dependent on exogenous catalyst concentrations - Improved in vivo performance of high-molar-activity radiopharmaceuticals - Less intrusive and damaging than current methods

Application

Cancer diagnosis and treatment. Can be used to induce selective compound degradation in vivo.

Inventors

Eszter Boros, Assistant Professor, Chemistry

Dariusz Śmiłowicz, Postdoctoral fellow, Chemistry

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available

Licensing Contact

Valery Matthys, Licensing Associate, Intellectual Property Partners, valery.matthys@stonybrook.edu,

Patent Status

PCT Filed

In-vivo data

Source: tiero, https://stock.adobe.com/uk/211799252, stock.adobe.com

Background

Aluminum is ubiquitous in many aspects of our life, from cans, to personal electronics, and to frames in automobiles. Though for many of these products, the aluminum should be as strong as possible. Dispersoids are important for increasing the strength of alloys and metals since they can bring alloys closer to their theoretical strengths that are usually decreased from imperfections such impurities or distortions in unit cells, allowing for stronger doped alloys such as steel. Though these processes are more structurally stronger, the cost of production is higher than traditional methods, limiting the output from the complicated nature of production or limited effectiveness from the size of the dispersoids.

Technology

Magnesium as a dopant is a great option, with its great oxidation potential and hydrides formed with magnesium decompose at about 400°C lower the overall sintering temperature, and allows for less formational variations resulting in stronger alloys that are slightly more brittle, but much stronger. In conjunction with high energy ball milling with a process control agent and sintering. The rate of milling and time spent is constantly tuned to get a single-phase solid solution, but a much richer solute rich second phase in the milled powders with menial cold welding. This achieves a higher percentage of dispersoids that are around 20 nm. This technology can help reduce the overall cost of production for most products that are constructed primarily from aluminum.

Advantages

Uses less energy to create alloy - Stronger alloy - Larger amount of 20nm dispersoids created - Consistent molecular unit cell groups

Application

Smoother metal products - Industrial alloy production

Inventors

Jason Trelewicz, Associate Professor, Materials Science and Chemical Engineering

Bin Cheng, Research Scientist, Materials Science and Chemical Engineering

David Sprouster, Assistant Professor, Materials science and Chemical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Patent application submitted

Source: Yuri Hoyda, https://stock.adobe.com/uk/565983722, stock.adobe.com

Background

Decarbonization of the power production, transportation, industrial and building heating sectors is pivotal for meeting net-zero carbon goals of 2050. As solar and wind are rapidly brought online to decarbonize the power grid, we are faced with the intermittent availability of renewable energy. Battery grid storage and pumped hydro has proven to be a significant lever to mitigate daily and weekly intermittency issues, but seasonal intermittency remains a challenge. Green hydrogen from renewable energy is already being worked on to solve renewable energy intermittency issues. However, hydrogen is difficult due to its low energy density and poor material compatibility. More complex fuel molecules such as ammonia (NH3) can solve the energy density problem and can readily be decomposed, on-demand, to generate hydrogen.

Technology

To overcome the high ignition temperature requirement and challengingly slow flame speeds associated with NH3 combustion by evaluating and understanding the use of a) laser-induced photochemical pathway for ammonia fuel decomposition into intermediate chemical species of NH2 and NH as well as b) laser-induced breakdown pathway for ammonia fuel ignition. By using laser ignition include high ignition location selectivity (single-, multi- focal spots) in combustion chamber, precise control of ignition timing and ignition energy correspond to active means of controlling ignition phenomena. This causes the ammonia to form unstable nitrogen intermediates and elemental hydrogen making the fuel more reactive. By using unstable intermediates as means of ignition the fuel becomes more reactive, but by using a laser the risk of NOX being the main pollutant is less likely to occur, without modification.

Advantages

High ignition location selectivity single and multi-focal spots - No quenching boundary - Energy costs of operating a portable laser - More environmentally conscious

Application

Can be applied to any vehicle that can use a combustion engine - Takes the place of a spark plug

Inventors

Dimitris Assanis, Assistant Professor, Mechanical Engineering

David Hwang, Assistant Professor, Mechanical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Publication No. Patent Pending

Source: graphicINmotion, https://stock.adobe.com/uk/189358568, stock.adobe.com

Background

As quantum computing technologies advance, managing magnetic flux becomes increasingly critical. Magnetic flux trapping is a persistent challenge that can degrade the performance of superconducting circuits, potentially leading to malfunction. Traditional methods for expelling magnetic flux, such as repeated thermal cycling or applying strong decaying alternating current magnetic pulses, are often time-consuming and energy-intensive. Innovative techniques for efficiently managing and mitigating magnetic flux are essential to ensure the continued progress of quantum computing technology.

Technology

Inventors at Stony Brook University have developed a groundbreaking system for the effective management and removal of trapped magnetic flux in superconducting circuits. This innovative system significantly enhances the performance of superconducting digital circuits by creating temperature gradients during thermal cycling, which efficiently expel residual magnetic flux. The system utilizes PCB traces as thermal links to deliver heat from the heating fixtures to the heating elements, resulting in a non-uniform temperature distribution that sweeps trapped flux away from magneto-sensitive areas.

Advantages

Efficient Flux Removal - Simple Integration - Stability and Reliability - Cost-Effective

Application

Quantum Computer Systems

Inventors

Anatoliy Borodin, Research Scientist, Physics and Astronomy

Yuri Polyakov, Senior Research Scientist, Physics & Astronomy

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Patent Pending

Source: amixstudio, https://stock.adobe.com/uk/239264395, stock.adobe.com

Background

Water shortages threaten the sustainability of human society and the efficient treatment of wastewater is required for recycling and discharge purposes. Wastewater released from textile and other industries generally contains toxic organic dyes and heavy metals, which may also cause substantial environmental problems. Among various technologies, adsorption has been considered as one of the most simple-implemented, cost-effective and highly efficient methods for wastewater treatment. In particular designing and fabricating high-performance adsorbents for a cleaner and more sustainable wastewater treatment is of great importance.

Technology

Cellulose scaffold, derived from glucose units with abundant hydroxyl sites, is biodegradable and non-toxic. This scaffold offers diverse routes for functionalization to enhance its ability to remove contaminants such as organic chemicals, dyes, and toxic metal ions from water. Cellulose is chemically modified to introduce cationic amine groups and C-H alkyl chains via a two-step reaction in water. These modifications transform cellulose into cationic dialdehyde celluloses (C-DAC), which exhibit high efficiency as adsorbents and coagulants for PFAS removal. C-DAC demonstrates rapid kinetics and strong affinity for both long and short-chain PFAS through electrostatic and hydrophobic interactions. Compared to traditional adsorbents like activated carbons, C-DAC shows particularly superior performance in removing short-chain PFAS compounds.

Advantages

Low cost alternative to tradition PFA filters - Removes major PFAs from water - Efficiently adsorbs organic dyes and heavy metals

Application

Water treatment plants - Home water filtration devices

Inventors

Duning Li, , Chemistry

Benjamin Hsiao, Distinguished Professor, Chemistry

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Patent Pending

Please note, header image is purely illustrative. Source, 12019, pixabay, CC0.

Background

In orthopedic surgery, accurately replicating preoperative plans during actual procedures is a significant challenge. Surgeons typically rely on preoperative imaging techniques such as X-rays, CT scans, and MRIs to create a 3D digital reconstruction of the patient's bone and develop a detailed surgical plan. However, translating these digital plans into precise surgical actions is fraught with difficulties. Traditional methods involve using physical tools like rulers and mechanical jigs, and estimating positions based on visible or palpable landmarks, which often results in inaccuracies. These inaccuracies can lead to suboptimal surgical outcomes, as the exact cutting planes and angles determined preoperatively are hard to replicate precisely during surgery. Additionally, the current methods for aligning and positioning surgical tools and jigs are cumbersome and time-consuming, often requiring repeated adjustments and intraoperative imaging, which exposes patients and staff to additional radiation and increases the cost and complexity of the procedure.

Technology

A surgical system for conducting bone surgery includes a camera to capture images and/or video, a projector to project light, and a controller that communicates with both the camera and projector. The controller tracks bone movement in real-time during surgery using the images and/or video from the camera. It controls the projector to project a cutting line on the bone, indicating the precise cutting plane for the surgery. The system also utilizes a marker attached to the bone, which includes a tracking component with a two-dimensional pattern or reflective features that the camera can recognize to monitor bone movement. The marker also has a registration component that, when scanned, helps determine the marker's position relative to the bone. The system can project alignment lines to guide the placement of a jig, ensuring accurate bone cuts as planned preoperatively. The projected lines adjust in real-time to account for any bone movement during the procedure, ensuring precision in surgical cuts.

Advantages

Higher Precision Bone Cutting - Reduction in Intraoperative Imaging - Real-time Adjustments - Enhanced Registration Accuracy - Cost-Effective Customization - Versatility in Jig Design - Improved Surgical Workflow - Non-Invasive Registration Options - Minimized Surgical Errors - Reduced Need for Large Equipment

Application

Orthopedic Surgery - Skeletal Deformity Correction - Placement of Surgical Screws, Pins, and Needles - Patient‑Specific Bone Repair

Inventors

Fazel Khan, Professor, Orthopedic Surgery

Imin Kao, Professor, Department of Mechanical Engineering

Guangyu He, , Department of Mechanical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available for licensing.

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Patent application submitted

https://patents.google.com/patent/US20230210609A1/en

Tran, stock.adobe.com

Background

Augmented reality (AR) has the transformative potential to seamlessly integrate digital information into the physical world, creating new opportunities for visualizing and interpreting 3D spatial scientific data. However, optical see-through head-mounted displays (OST-HMDs) pose significant challenges for accurate visualization due to the blending of virtual content with the real-world environment. This blending can lead to inaccurate perception of rendered pixels, which is particularly problematic for scientific visualization. Traditional approaches have attempted to address these issues by focusing on separate objectives such as intuitive placement, visibility enhancement, and color correction of virtual objects. Volume rendering, which maps data attributes to optical properties like color and opacity using transfer functions (TFs), faces additional challenges in AR due to the difficulty in maintaining perceptual mapping and discernibility against real-world backgrounds. Existing solutions often fail to consider the coupled problem of placement and color constraints or do not adequately address the specific needs of volume visualization, resulting in suboptimal user experiences and potential inaccuracies in data interpretation.

Technology

VoxAR is a method designed to enhance the visualization of volume-rendered objects in optical see-through head-mounted displays (OST-HMDs). It addresses the challenge of rendered pixels blending with real-world colors, which can hinder accurate perception of augmented information. The system operates in two primary steps: first, it determines the optimal placement of virtual objects in the user's field of view by evaluating spatial and environmental objectives using a GPU shader language. This ensures that the placement is managed according to user preferences and predefined constraints. Second, VoxAR adjusts the colors of the transfer function (TF) used for volume rendering based on the real-world background. This adjustment is achieved through a novel optimization method that ensures the rendered pixels are distinguishable from the background while maintaining the perceptual mapping between colors and data intensity values. The system is implemented in Unity3D for the Microsoft Hololens2 and includes a real-time solution for evaluating and optimizing the placement and visualization of virtual objects. The effectiveness of VoxAR is validated through both objective evaluations and subjective user studies, demonstrating significant improvements in the user's ability to perceive and analyze volume-rendered visualizations in augmented reality.

Advantages

Optimal Placement of Virtual Objects - Color Discernibility Optimization - Real-Time Performance - Preservation of Perceptual Mapping - Support for Changing Field of View (FoV) - Enhanced User Performance - Compatibility with Existing AR Systems

Application

Scientific Visualization - Medical Visualization - Situated-AR Visualizations - Educational and Training Applications - Collaborative Data Analysis

Inventors

Arie Kaufman, Distinguished Prof. & Chair, Computer Science

Saeed Boorboor, Principal Research Scientist, Computer Science

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available for licensing.

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

Provisional patent

Header image is purely illustrative. Source: ra2 studio, stock.adobe.com/uk/68910992

Background

Writing text using eye-gaze input is a promising hands-free method, particularly beneficial for individuals with motor disabilities or in environments where physical keyboards are impractical, such as virtual or augmented reality settings. Traditional gaze-based text entry methods, which often require users to dwell on each letter for a certain period, can be slow and induce significant eye fatigue. Although dwell-free methods have been explored, they typically involve complex gestures or additional actions to mark the start and end of a gaze path, such as "reverse crossing" or the use of supplementary input modalities like touch. These requirements can be cumbersome, time-consuming, and still prone to errors, limiting the efficiency and usability of gaze-based text entry systems. Consequently, there is a need for an intuitive, fast, and accurate gaze-based text entry method that minimizes the physical and cognitive demands on the user while eliminating the need for additional actions to specify gaze path boundaries.

Technology

GlanceWriter is a text entry method that allows users to input text by glancing over keys on a virtual keyboard without the need for dwelling or marking the start and end of a gaze path. It uses a probabilistic decoding algorithm that determines which letters are being typed based on the dynamics of gaze movements and their locations. The system probabilistically decodes the gaze path by examining gaze motion stability and distances to key centers, assigning scores to keys to indicate the likelihood of selection. These scores are aggregated to form word scores, which are then combined with a language model to predict the intended word. The method eliminates the need for "reverse crossing" or other additional actions, streamlining the text entry process. User studies have shown that GlanceWriter significantly improves text entry speed and reduces error rates compared to existing gaze-based text entry methods, making it a promising solution for hands-free text input, especially beneficial for individuals with motor disabilities or in environments where physical keyboards are impractical.

Advantages

Higher Typing Speed - Lower Error Rate - Elimination of Dwell Time - No Reverse Crossing Required - Probabilistic Decoding Algorithm - Improved User Comfort - Ease of Error Correction - Better Handling of Gaze Instability - Flexible Gaze Path Ending

Application

Assistive Technology for Individuals with Motor Disabilities - Virtual and Augmented Reality Environments - Medical and Rehabilitation Settings

Inventors

Rui Liu, ,

Wenzhe Cui, , Computer Science

Xiaojun Bi, Assistant Professor, Computer Science

Fusheng Wang, Assistant Professor, Biomedical informatics & Computer Science

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available for licensing.

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

No patent

Source: Vasyl, https://stock.adobe.com/uk/374849081, stock.adobe.com

Background

In educational settings, both online and offline, monitoring and responding to students' emotional states can significantly enhance learning outcomes. Traditional approaches rely heavily on subjective observations by teachers, which can be inconsistent and limited by human perception and attention. In online environments, the challenge is even greater due to the physical separation between students and instructors, making it difficult to gauge engagement and emotional responses accurately. Existing methods often lack real-time adaptability and fail to provide personalized interventions, thereby affecting the overall efficacy of the learning experience. Additionally, the need for specially designed teaching materials and prerecorded content to accommodate emotional responses adds complexity and resource demands. These limitations highlight the necessity for more sophisticated, real-time emotion-sensing technologies that can seamlessly integrate into both online and offline educational frameworks.

Technology

Sensemo is designed for both online and offline learning environments, utilizing smartwatches to collect real-time physiological signal data from students. This data is transmitted to a server via an Android app for further processing. In online learning, the system adapts the learning experience by adjusting the speed or content based on the student's emotional responses, either automatically or through teacher intervention. Teachers can monitor and override the system's actions as needed, using specially designed teaching materials and prerecorded lecture segments. In classroom settings, lecturers use the emotional feedback to engage in interactive learning, aiming to maintain positive emotional responses among the majority while addressing individual needs.

Advantages

Real-time Emotion Monitoring - Adaptation of Learning Material - Teacher Override Capability - Interactive Classroom Learning - Unified Online and Offline Application - Physiological Data Utilization - Enhanced Student Engagement

Application

The system monitors individual students' emotional responses in real-time and adjusts the speed or content of the lesson to enhance engagement and learning outcomes. Lecturers can use real-time emotional feedback from students to tailor their teaching methods, ensuring a positive emotional response from the majority and addressing the needs of less engaged individuals.

Inventors

Shan Lin, Assistant Professor, Electrical Engineering

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Available for licensing

Licensing Contact

James Martino, Licensing Specialist, Intellectual Property Partners, james.martino@stonybrook.edu,

Patent Status

No patent

Background

The widespread adoption of renewable energy and the electrification of transportation has led to an increased need for rare earth materials. The proposed technology aims to mitigate this dependency by strategically optimizing product design elements, including the geometry of permanent magnets, irons, and other electrical system parameters. Through systematic co-optimization, researchers at Stony Brook University (SBU) ensure an optimal design at the system level, thereby reducing reliance on rare-earth metals.

Technology

Researchers at SBU have introduced an innovative approach to lessen reliance on rare-earth materials through the application of topology optimization in electric machine design. Topology optimization, a mathematical technique, optimizes material distribution within a defined design space. In this case, this method is employed on permanent magnets utilized in power generators, effectively reducing material usage while maintaining optimal performance. This methodology is grounded in a level-set-based parametric approach, enabling seamless integration with model-based co-design tools. Through this comprehensive approach, they achieve functional optimization at both the component and system levels of electric machine design.

Advantages

Reduce dependence on expensive rare‑earth materials - Generate innovative designs

Application

Integrates topology optimization with model‑based co‑design tools - Handles multi‑physics and multi‑material magnet topology optimization problems

Inventors

Shikui Chen, Associate Professor, Mechanical Engineering

Jiawei Tian, Ph.D. Candidate, Mechanical Engineering

Fang Luo, Associate Professor, Electrical Engineering

Jon Longtin, Associate Professor, Mechanical Engineering

Xianfeng Gu, Assistant Professor, Computer Science

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Contact

Donna Tumminello, Assistant Director, Intellectual Property Partners, donna.tumminello@stonybrook.edu, 6316324163

Patent Status

No patent

Background

Medical imaging has made significant strides over time, with automatic segmentation emerging as a pivotal component in various medical realms, including diagnosis, treatment planning, and research. This technique involves extracting regions of interest from medical imagery, such as CT scans and MRI, without reliance on manual intervention. The proposed research endeavors to develop a system and methodology for the automated segmentation of multiple organs across diverse modalities of medical imaging.

Technology

Researchers at Stony Brook University (SBU) have developed a novel methodology and system for automating multi-organ segmentation in medical imaging. This approach entails training a neural network conditionally, leveraging annotated medical images to delineate target organ boundaries. Through this process, the model acquires an understanding of spatial relationships among labels, enhancing its capacity for generalization. The base component of this system is a 3D fully-convolutional neural network which is a deep learning architecture enabling AI to respond to input data dynamically, rather than adhering to pre-defined algorithms. The system allows for efficient training for multi‑label segmentation on single‑label datasets.

Advantages

Time‑efficient - Easier to generate - Increased accuracy of segmentation outlines

Application

Annotates imaging parameters in multi‑class image segmentation models derived from single‑label datasets

Inventors

Arie Kaufman, Distinguished Prof. & Chair, Computer Science

Konstantin Dmitriev, PhD Student,

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Contact

Donna Tumminello, Assistant Director, Intellectual Property Partners, donna.tumminello@stonybrook.edu, 6316324163

Patent Status

Patented

https://patents.google.com/patent/US20220237801A1/en?oq=17%2f614%2c702

Please note, header image is purely illustrative. Source: Gorodenkoff, stock.adobe.com

Background

Spectral CT is an imaging modality that allows for tissue‑specific texture differentiation, along with anatomical information provided by conventional CT. However, current methods of image reconstruction for spectral CT fail to fully take advantage of this potential, and result in degradation of texture quality. Texture is a crucial feature used to distinguish healthy tissue, benign lesions, and malignant lesions. Conventional CT and current spectral CT methods often lack sufficient texture quality required for diagnosis, resulting in misdiagnosis, unnecessary invasive procedures, missed and untreated lesions, or increased radiation dosage due to further imaging.

Technology

This technology utilizes artificial intelligence to improve spectral CT reconstruction tissue‑specific texture quality and assist in computer‑aided lesion diagnosis, improving the capabilities of spectral CT scanning for lesion diagnosis. The reconstruction of the spectral CT images is achieved by considering the structural similarity among the energy spectral channels, the tissue-specific textures in each energy channel, and spectral data statistics. The ultimate goal is to enhance the tissue-specific textures in each energy channel by using the structural similarity among all energy channels, the tissue-specific textures in each energy channel, and the data statistics, all in a single equation. Using the improved images, texture-based computer-aided diagnosis (CADx) is able to fully utilize the energy spectral tissue-specific textures for lesion diagnosis. The addition of this energy spectral tissue-specific texture CADx can maximize the potential benefit of CT scanning for medical diagnosis.

Advantages

Improved texture quality for spectral CT images - Increased differentiation of tissue‑specific textures in CT images - More accurate texture‑based computer‑aided diagnosis of lesions

Application

Medical imaging (Hospitals, Radiology clinics, Cancer centers) - Research

Inventors

Jerome Liang, Professor, Radiology

Yongyi Shi, Research Assistant, Radiology

Yongfeng Gao, Postdoctoral Researcher, Radiology

Licensing Potential

Development partner - Commercial partner - Licensing

Licensing Status

Licensing Contact

Donna Tumminello, Assistant Director, Intellectual Property Partners, donna.tumminello@stonybrook.edu, 6316324163

Patent Status

No patent