By Daniel Dunaief

One of the seminal, and realistic, scenes from the movie “The Martian” involves astronaut

Mark Watney, played by Matt Damon, clearing the dust from a solar panel.

The cleaning process not only made it possible for the space station on Mars to continue

to generate solar energy, but it also alerted the National Aeronautics and Space Administration

staff on Earth to the fact that Watney somehow survived a storm and was alive and

stranded on the Red Planet.

Alexander Orlov Photo from SBU

Back in 1967, engineers from NASA proposed a system to remove dust from solar panels,

which can deprive space stations of energy and can cause rovers and other distant

remotely operated vehicles to stop functioning. Washing these solar cells on dried

out planets with water is not an option.

That’s where Alexander Orlov, a Professor of Materials Science and Chemical Engineering

in the College of Engineering and Applied Science, his graduate student Shrish Patel,

Victor Veerasamy, Research Professor of Materials Science and Chemical Engineering

at Stony Brook University, and Jim Smith, Chief Technology Officer at Bison Technologies

and a board member at the Clean Energy Business Incubator Program at SBU, come in.

Working at a company Orlov founded called SuperClean Glass, Orlov, Patel and other

colleagues tried to make an original effort started by NASA feasible. The particles

have an electric charge. An electric field they created on the solar glass lifts the

particles and then throws them away.

The process recently became a finalist in the Department of Energy’s American-Made

Solar Prize for 2021. The 10 companies who are finalists get a $100,000 prize and

$75,000 in vouchers from the Department of Energy to test their technology.

The DOE will announce two winners in September of 2021, who will each get an additional

half a million dollars and $75,000 in vouchers to develop and test their prototypes.

Orlov, who was delighted that this effort received the recognition and the funds,

said the company would use the money to develop prototypes and verify that ‘this technology

works at the National Renewable Energy Lab.”

SuperClean Glass is creating prototypes of larger scale to show that turning on a

power supply will cause dust to levitate and be removed within seconds.

At this point, Orlov estimates that companies can recoup the additional cost of using

this technology within four to five years. The average lifespan of a solar panel is

about 25 years, which means that companies could increase their energy efficiency

for the 20 years after the initial investment in the technology.

Orlov said the current state of the art for cleaning solar panels typically involves

using either water, getting people to dust off the surface, or deploying robots.

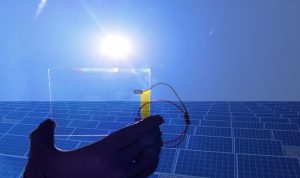

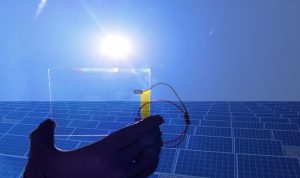

This device used for experiments is a highly transparent electrodynamic shield deposited

on glass to repel dust from solar panels. Image courtesy of SuperClean Glass Inc

In Egypt, where labor costs are lower, companies can pay people to remove dust with

brushes. While robots reduce the cost of labor, they are not always efficient and

can break down.

Some companies put a coating on the panels that allows rainwater to wash the dust

away more easily. That, however, relies on rain, which is scarce in desert conditions.

Orlov originally became involved in trying to develop an alternative to these methods

when Sam Aronson, the former director of Brookhaven National Laboratory, contacted

him following a visit to the Turkana Basin Institute in Kenya.

When he visited the archeological site in Kenya, Aronson saw that dust frequently

reduced the efficiency and effectiveness of the solar panels. The dust problem is

not specific to Kenya or the United States, as many of the most attractive sites for

solar panels are in regions with considerable sun and little rainfall. The benefit

of minimal precipitation is that it provides access to critical sunlight, which generates

energy.

The downside of these sites, however, is that the dry, sunny climates often produce

dust.

Orlov researched the NASA technology, where he discovered that it wasn’t efficient

and couldn’t be scaled up.

Using $150,000 he received from the New York State energy Research and Development

Authority, or NYSERDA, Orlov and Patel started reaching out to solar panel manufacturers

to determine the price point at which such a dust cleaning removal service might be

viable.

“We conducted interviews with 180 people who use solar panels to find out the particular

price point where this technology becomes attractive,” Orlov said. That was the steep

curve, to do economic analysis, financial projections and to understand what the market

wants. All that is not present in [typical] academic research.”

They reduced the power consumption for electrodes by a factor of five. They also explored

commercial methods for scaling up their manufacturing approach.

Dust isn’t the same throughout the world, as it is a different color in various areas

and has different mineral contents.

“In the future, depending on where this might be deployed, there needs to be some

tweaking of this technology,” Orlov said.

As a part of the technology roadmap for the work they are proposing, the SuperClean

effort includes a self-monitoring system that would activate the electrodes on the

shield if needed to repel an accumulation of dust.

Orlov described the market for such a self-cleaning and efficient process as “very

significant.” He is hoping to provide a field demonstration of this approach later

this year. If the process continues to produce commercially viable results, they could

license the technology within two to three years.

In the near term, Orlov is focused on producing results that could enhance their positioning

for the DOE’s grand prize.

“There are a lot of steps before September to be eligible” to win the $500,000, he

said. The biggest hurdle at this point is to get positive results from the National

Renewable Energy Lab and demonstrate that the technology is effective and also durable.

“Our expectation is that it should last for 25 years, but the lab, which is going

to do the testing, is the gold standard to verify that claim,” he said.